Fire Alarm Reporting

Fire Alarm Reporting Anyone that owns a building with a fire alarm system knows the importance of getting a clean inspection report. It keeps both

Rob Read

Rob Read is the Founder and CEO of Bison Fire Protection. He has been in the fire protection industry since 1991, growing from refilling fire extinguishers to owning and expanding Bison Fire Protection. The success Rob has had with Bison Fire Protection comes in many forms — from making the Profit 500 list of Canada’s fastest-growing companies in 2012-2019 to being a finalist of Manitoba’s Most Outstanding Medium Businesses and receiving many manufacturers’ awards for sales and service, to the greatest award of all, repeat and referred business from our customers.

Fire Alarm Reporting Anyone that owns a building with a fire alarm system knows the importance of getting a clean inspection report. It keeps both

Manitoba OFC Bulletin # OFC2023-03 In October of 2023 the Office of the Fire Commissioner issued Bulletin # OFC2023-03. This bulletin is specifically for “Special

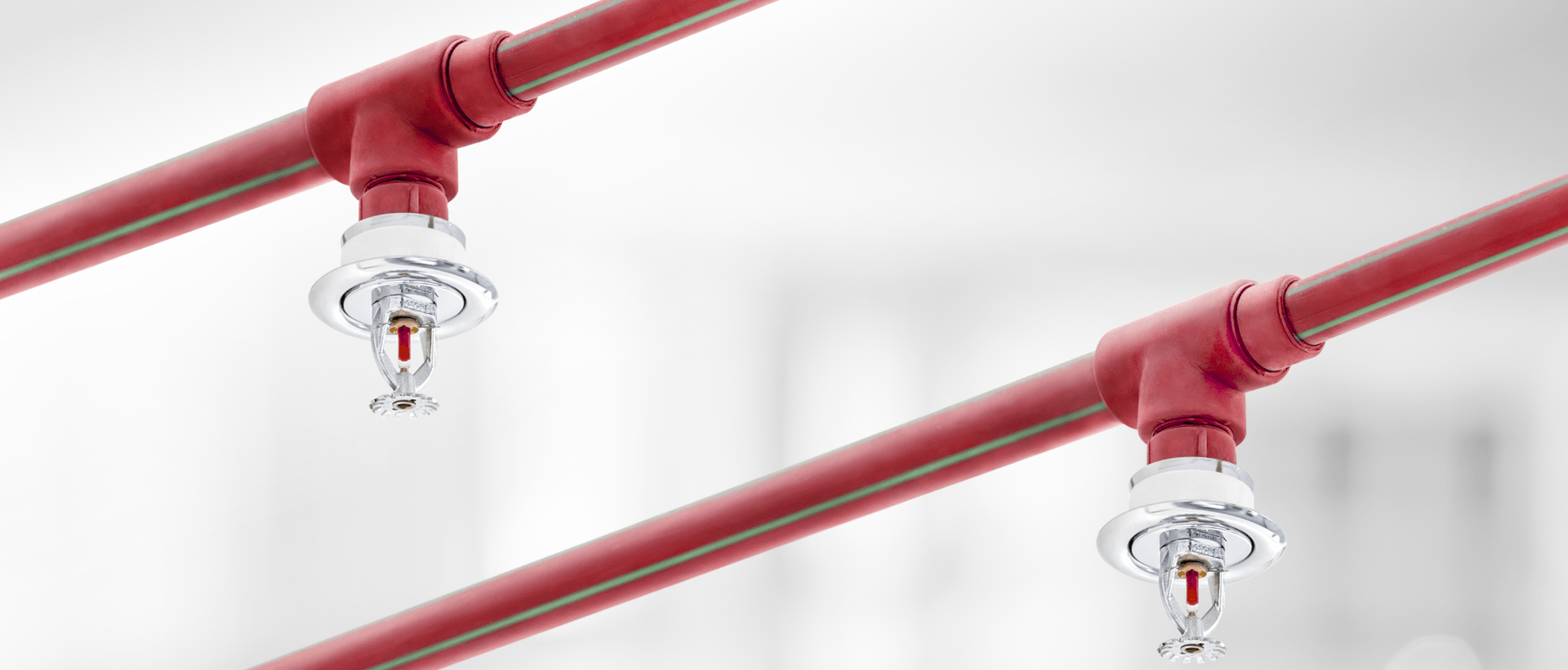

Are you concerned about the reliability of your building’s sprinkler system? As with any mechanical system, your sprinklers need regular maintenance to ensure that they

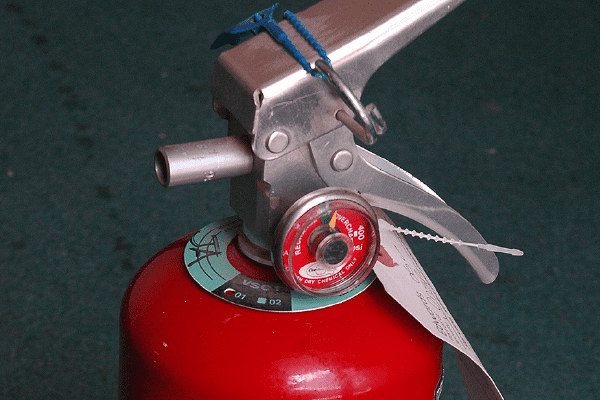

What if you think you have a functional fire extinguisher, but then you find out, during an emergency, that they’re not? It’s like walking on

When it comes to protecting your business, having the right fire prevention company on your side is crucial. Proper certifications, the right product lines, well-equipped

Imagine monitoring your fire safety system wherever you are, using whatever device you have available. Imagine having the ability to monitor multiple sites without ever

From its first invention in 1819, fire extinguishers have been an essential fire safety equipment in every establishment. This humble piece of equipment is everywhere,

In 2019, a fire protection company in Alberta was charged a total of $300,000 for sending uncertified technicians to inspect fire safety systems on their

You think it won’t happen to you until it does. Catastrophic fires occur when you least expect it and worse, 80% of businesses never recover

Every year fire accounts for the loss of millions of dollars and thousands of lives. Taking the time to ensure your fire sprinkler system is

Most of you know that having a fire extinguisher at home or in your business is important. But did you know that most people forget

Over the years we have had the pleasure of protecting the people of Manitoba with fire protection services they need and can count on. We

Recent Posts

35 Boys Road

Springfield, Manitoba

R5R 0J6

Phone : (204) 237-3473

Fax : (204) 237-4744

E-mail: info@bisonfire.com

1771 Mcara Street

Regina, Saskatchewan

S4N 6H5

Phone: (306) 546-5305

Fax: (306) 546-5293

Toll Free: (877) 608-5463

E-mail: info@bisonfire.com

830 Stickney Ave

Brandon, Manitoba

R7A 0C9

Phone: (204) 727-6477

E-mail: info@bisonfire.com

B-200 Hayes Rd

Thompson, Manitoba

R8N 1M4

Toll Free: (888) 778-6848

Phone: (204) 778-6848

Fax: (204) 778-4440

E-mail: info@bisonfire.com

35 Boys Road

Springfield, Manitoba

R5R 0J6

Phone : (204) 237-3473

Fax : (204) 237-4744

E-mail: info@bisonfire.com

830 Stickney Ave

Brandon, Manitoba

R7A 0C9

Phone: (204) 727-6477

E-mail: info@bisonfire.com

1771 Mcara Street

Regina, Saskatchewan

S4N 6H5

Phone: 306-546-5305

Fax: (306) 546-5293

Toll Free: (877) 608-5463

E-mail: info@bisonfire.com

B-200 Hayes Rd

Thompson, MB

R8N 1M4

Toll Free 888-778-6848

PH: 204-778-6848

Fax: 204-778-4440

E-mail: info@bisonfire.com

Thompson office is moving on Nov 30, 2022

The new address is: B-200 Hayes Rd, Thompson, MB R8N 1M4